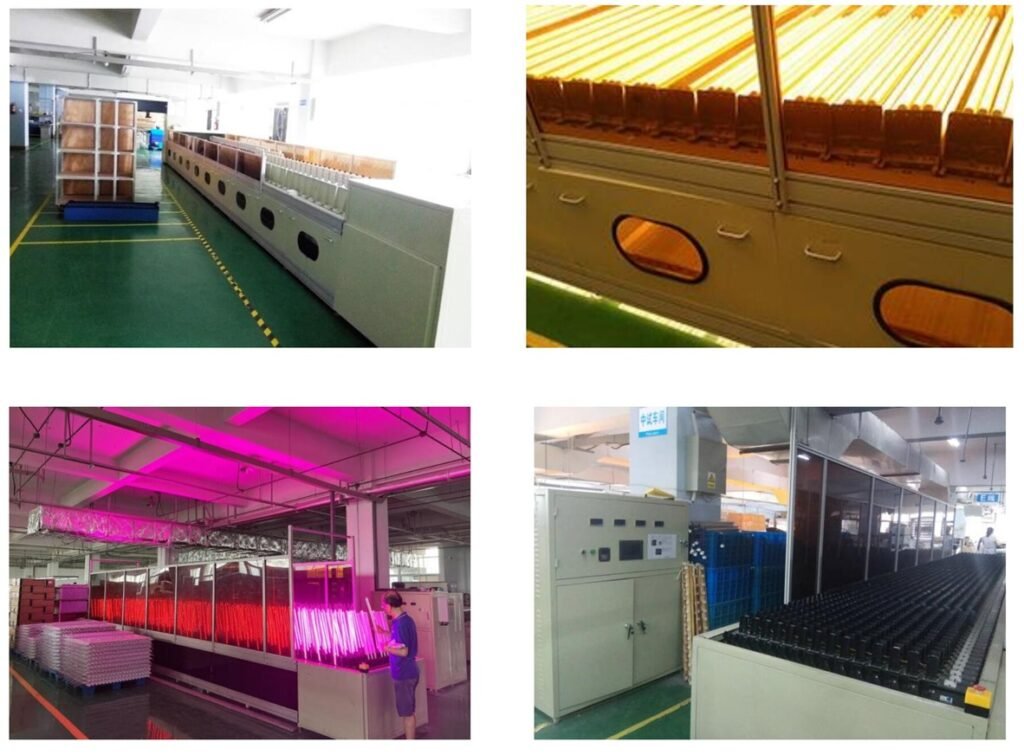

Quality Control

ISO Compliant Production Cycle

Our manufacturing system operates in a meticulously monitored, dust-free environment to uphold the highest standards of quality.

>Our lights are crafted using superior raw materials, ensuring longevity and durability.

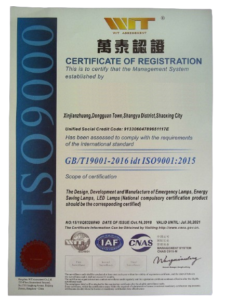

>Our production process, certified by ISO 9001, ISO 4001, OHSMS 18000, epitomizes efficiency.

>Thanks to our highly skilled workforce and effective interdepartmental collaboration, our manufacturing process is seamless and optimized.

>Furthermore, we conduct extensive and varied testing methods to guarantee the utmost quality of all our products.

Esteemed Partners in Supplying Premium Raw Materials

CREE

The best lighting-class LED manufacturers.

OSRAM

Worldwide market leader in lighting-class LEDs.

Philips

Worldwide market leader in soft filament LEDs.

MEAN WELL

The outstanding outdoor LED Driver suppliers.

INVENTRONICS

The leading outdoor LED Driver manufacturer.

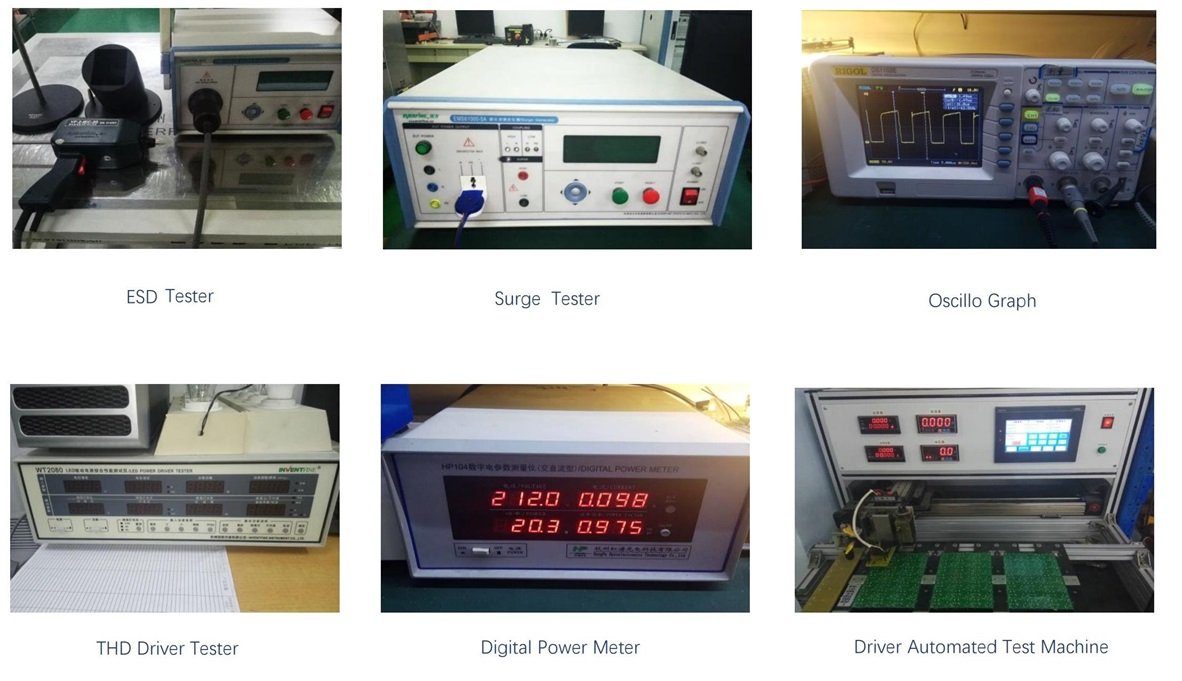

Our Product Testing Protocol

We perform 13 tests to produce our top-quality and reliable LED Garden Lights and Christmas Lights. Out of these, a few are listed below.

High-Temperature Test

This examination involves immersing the products in 85° hot water for 1.5 hours. In line with our stringent quality guidelines, any components that malfunction are promptly identified and removed.

High-Pressure Spray Test

The outdoor lighting products, including landscape lights and facade LED lights, undergo a test where they are exposed to a simulated hot water spray, with temperatures ranging from 65° to 90°, for approximately 1.5 hours. This procedure is crucial for identifying and filtering out any defective units in these products.

Photometric Parameters Test

Each of these tests requires specialized equipment and expertise. The results are used to certify the quality and performance of lighting products according to industry standards and regulations, ensuring they are safe and effective for consumer or professional use.

EMC & EMI Test

EMC and EMI testing for lighting products is essential for both consumer safety and legal compliance. These tests are usually conducted in specialized labs with appropriate equipment to simulate a variety of electromagnetic conditions. Successful completion of these tests results in certification that the product is electromagnetically compatible and won’t cause or suffer from interference in normal operation.

HPG Distributed Photometer Test

Provides manufacturers and quality assurance teams with critical information about the performance of their lighting products. It ensures that these products meet industry standards, provide efficient and high-quality lighting, and are suitable for their intended applications. This test is especially important in industries where precise lighting characteristics are crucial, such as in automotive lighting, street lighting, and commercial lighting applications.

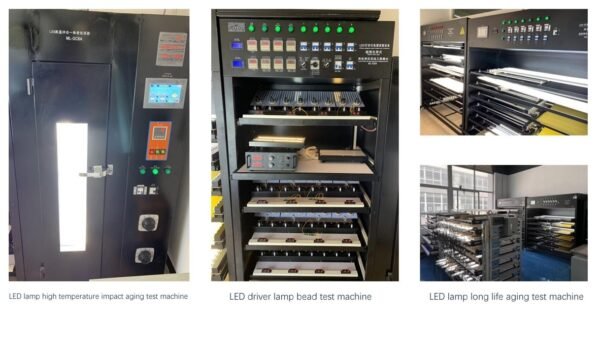

Aging Test

It’s essential for manufacturers to guarantee that their lighting products will perform reliably over their intended lifespan, providing consumers with both safety and value. This testing is particularly important for products with long life claims, such as LED lighting, where consumers expect many years of consistent and trouble-free operation.

Testing Equipments For Technical Department and Quality Control Department

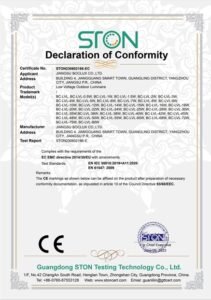

Certificates

ISO9001

ISO4001

CE

ErP

eTL